PIT - Competitive advantage for production & service

Reduce manufacturing costs by producing more sustainably and economically – or reduce operating costs by avoiding machine and plant downtimes.

- Reproducible increase in fatigue strength

- Extension of remaining service life

- Cost and time savings compared to conventional methods

- Reduction of shrinkage stress/distortion

- Better component safety against fatigue

- Significant potential in lightweight construction

- Prevention of stress corrosion cracking

Some of the customers who trust us

Find out the range of benefits that the PIT process offers you specifically:

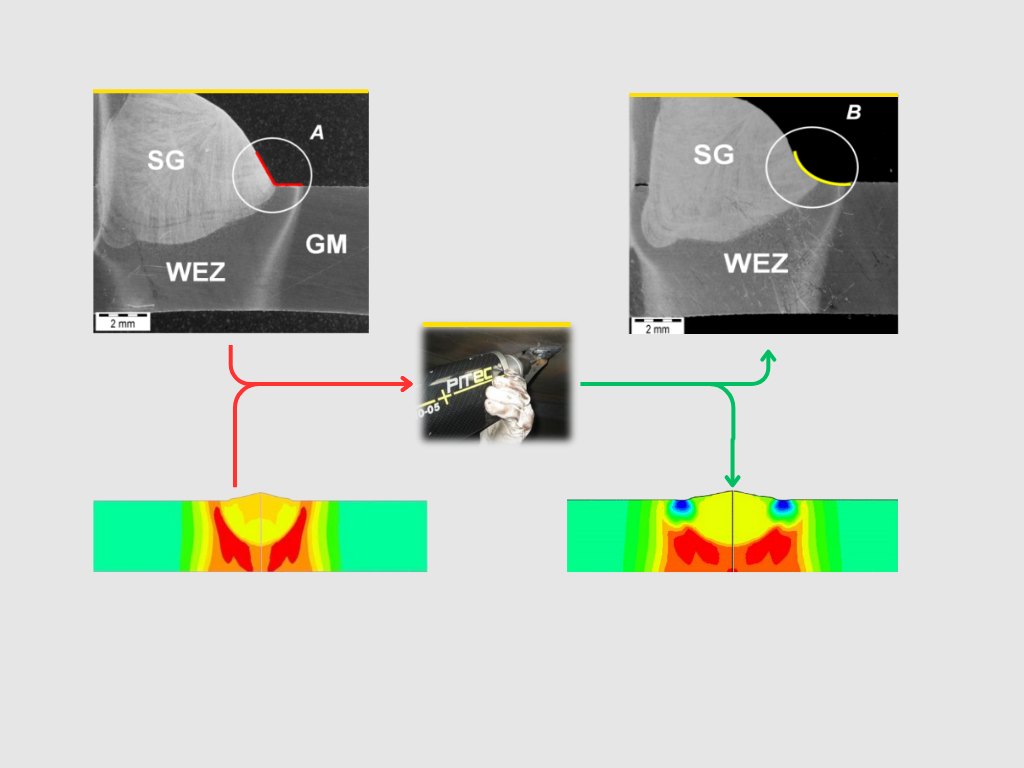

What is the PIT Effect?

Pneumatic Impact Treatment (PIT) is a reproducible process that intentionally induces residual compressive stresses in critical areas of your components, simultaneously optimizing the geometry at the weld seam transition. As a result, it counteracts the development of fatigue cracks at the formation stage.

In addition to the repeated scientific validation of the HFMI (High-Frequency Mechanical Impact) effect, the University of Stuttgart specifically confirmed PIT’s high level of reproducibility without the risk of over-treatment.

(Study Link: Investigation of HFMI with variable execution quality))

About PITEC

Since 2008, PITEC has rapidly emerged as the global leader in the field of HFMI (High-Frequency Mechanical Impact). Through many years of experience and continuous development, PITEC has established itself as the international leader. In 2018, PITEC was acquired by Hermann Fliess & Co. GmbH .

Fliess is a manufacturer of welding consumables with particular expertise in high-strength steels. With PIT enabling the use of high-strength steels even under fatigue conditions, a unique synergy arises.

Would you like to gain a competitive advantage?

I am interested in:

Use cases of PIT

The SMS Group is constructing, on behalf of the OTTO FUCHS Group, at the Paramount USA site, within the subsidiary Weber Metals, the new hydraulic press with a force of 540 MN. To achieve the required strength values according to FKM, the SMS Group decided to treat the free surfaces of the bores extensively with our PIT process, thereby introducing high compressive residual stresses deep into the surface.

It’s noteworthy that, despite a total area of over 8m², SMS chose PIT over shot blasting.

In the steam drums of the heating plant at Stadtwerke München, despite professional repairs, cracks in the inner circumferential seams occurred repeatedly. In May 2011, in cooperation with TÜV Süd, the decision was made to treat the entire seam area including the heat-affected zone (HAZ) on two drums with PIT.

However, due to the high operating temperatures exceeding 500° C, we at PITEC were skeptical whether the introduced compressive residual stresses would be excessively reduced, potentially impacting a sustainable effect.

In February 2020, the PIT team learned that no new cracks have appeared in the PIT-treated area during regular inspections, even to date.

At the ArcelorMittal plant in Ghent, Belgium, in 2012, 8,000 cracks were detected in the crane system area.

Durch das R&D-Projekt im eigenen Institut OCAS erkannten sie 2014, nach eigenen Versuchen, PIT als die vielversprechendste Lösung und führten das Verfahren in der Instandsetzung ein.

Starting immediately, repair seams and yet undetected hot spots were proactively treated with PIT.

Five years later, in 2019, the number of detected cracks had dropped to only 700. This represented a reduction of over 90%!

After cracks in the upper beam of the 200 MN press were mechanically prepared, the repair welding specialist Casper Hahn reconstructed the material through welding techniques.

To prevent warping of the beam due to the large amount of welding material and the associated shrinkage stresses, it was decided to treat each layer extensively with PIT.

Subsequently, pressure residual stresses were introduced into the particularly stressed areas using PIT to enhance the fatigue strength of the press.