Reduce costs by avoiding equipment failures due to fatigue cracks.

PIT offers you:

- Reproducible increase in fatigue strength

- Prevention or avoidance of fatigue damage, even in structures already under load

- Extension of remaining service life

- Prevention of stress corrosion cracking

- Retrofitting even for the base frame of machinery and equipment

Some of the customers who trust us

An untimely equipment failure due to cracks catches you off guard, causing complex issues for the entire company?

Your maintenance and production managers repeatedly face these challenges:

- Your entire operations come to a halt due to fatigue cracks.

- Orders are delayed.

- Despite extensive repairs, fatigue damage continues to occur.

- High costs are incurred for downtime and repairs.

- Equipment requires costly renovation.

Here's how we support you in reducing or entirely avoiding equipment failures caused by cracks while keeping your operations running:

What becomes possible with the PIT process:

You proactively prevent the formation of fatigue cracks...

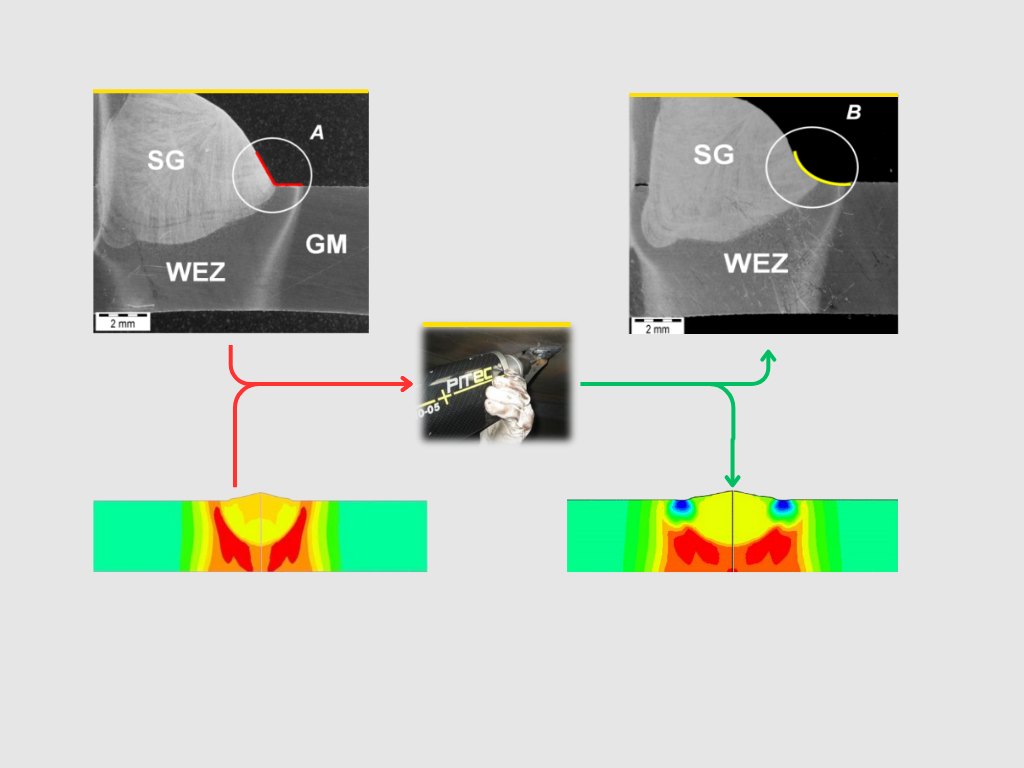

...because the PIT process deliberately induces compressive residual stresses in your equipment’s hotspots, effectively counteracting the formation of fatigue damage. This significantly extends the remaining service life of your equipment.

You avoid recurring repairs and their consequences...

...because the PIT process not only prevents fatigue damage, but also significantly increases the lifespan of repair seams during maintenance.

You save costs because the PIT effect lets you continue operating existing and thus pre-stressed structures...

...which allows for a refresh of the base structure, particularly when retrofitting.

PIT - The internationally leading HFMI process

Pneumatic Impact Treatment (PIT) is a reproducible process that intentionally induces residual compressive stresses in critical areas of your components, simultaneously optimizing the geometry at the weld seam transition. As a result, it counteracts the development of fatigue cracks at the formation stage.

In addition to the repeated scientific validation of the HFMI (High-Frequency Mechanical Impact) effect, the University of Stuttgart specifically confirmed PIT’s high level of reproducibility without the risk of over-treatment.

(Study Link: Investigation of HFMI with variable execution quality) )

PIT - The leading HFMI process with confirmed effectiveness that’s already listed in the following regulatory frameworks:

Ways to capitalize on the comprehensive advantages of the PIT process :

- PIT application consultation

- PIT system sales

- PIT accessories

- PIT user training

- PIT services

- PIT rental equipment

- PIT quality monitoring

PIT application consultation

Benefit from our extensive experience and receive tailored advice based on your individual needs. We’ll demonstrate the potential of a PIT treatment perfectly tailored to your use case.

PIT system sales

Our PIT System Weld Line 10 is suitable for both manual use and robot automation.

Additionally, we offer a PIT System designed for underwater use.

PIT accessories

In addition to a wide range of different bolt radii and lengths, PITEC also offers high-quality tools such as an LED magnifier for visual inspection and a PIT Intensity Kit for regular impact intensity checks.

PIT user training

Thanks to the hands-on training, your employees will gain a thorough understanding of the technology, enabling a smooth and swift integration of the process with sustainable quality.

PIT services

Let our experienced team assist you with PIT treatment worldwide – benefit from the PIT effect on demand!

PIT rental equipment

Do you only need our high-quality PIT systems temporarily? No problem! We're happy to provide you with our rental equipment.

PIT quality monitoring

If you have suppliers or partners utilizing PIT, we offer quality monitoring as a "third-party" service as needed.

How can we collaborate?

Non-binding informational session

Gain detailed insights into how you specifically can benefit from the PIT process.

Presentation

You’ll receive a comprehensive presentation on PIT technology (in- person/online).

Assessment of your requirements:

Together, we'll determine not only how we can support you in your upcoming project, but also the extensive opportunities that a PIT treatment creates for you and your company.

Proposal

You'll receive a tailored proposal specific to your individual use case.

About PITEC

Since 2008, PITEC has rapidly emerged as the global leader in the field of HFMI (High-Frequency Mechanical Impact). Through many years of experience and continuous development, PITEC has established itself as the international leader. In 2018, PITEC was acquired by Hermann Fliess & Co. GmbH .

Fliess is a manufacturer of welding consumables with particular expertise in high-strength steels. With PIT enabling the use of high-strength steels even under fatigue conditions, a unique synergy arises.

Do you still have questions? We have answers.

Send us a message and we’ll get in touch soon.

Questions and Answers

The sound level of a PIT application isn’t determined by the PIT device, but by the resonating body of the component being treated. As a rule, the application is no louder than working with an angle grinder.

The construction can be designed according to FAT or FKM recommendations and the required PIT treatment can be specified at the appropriate points using a dash-dotted line. vorgegeben werden.

The first step some of our customers take is to use a general work instruction to replace conventional methods like grinding or TIG dressing with a PIT application.

Through the practical user training, which takes 4-6 hours, users learn everything necessary to ensure correct PIT application with appropriate quality.

In addition to the repeated scientific validation of the HFMI (High-Frequency Mechanical Impact) effect, the University of Stuttgart specifically confirmed PIT’s high level of reproducibility without the risk of over-treatment. This study also confirms that a 100% visual inspection of the treatment track in terms of position and possible residual notches is sufficient.

PITEC manufactures its devices with high-quality components from reputable manufacturers in Germany. The devices are designed for industrial use. Taking the company Trumpf Haguenau as an example, our devices sold in 2009 are still in operation today.